Innovative devices simulate human organ responses

Organ-on-a chip? Yes, it is possible. And INESC-ID will give a hand to it

Tiago Moita walks across the wooden floor in what appear to be ordinary rubber-soled shoes. However, there’s a twist: a low electrical resistance shoe sole prevents static electricity from damaging the microchips developed and tested at the Silicongate workbench. This company, incubated and partly owned by INESC-ID, designs and tests circuits for power management systems, such as those used in mobile phones. Strongly committed to research and innovation, Silicongate also participates in research projects like the EU-funded UNLOOC initiative, aimed at transforming the drug development process by reducing reliance on animal testing.

Traditional animal testing in drug development faces significant challenges due to methodological limitations and ethical concerns, often failing to predict human reactions to drugs. It is estimated that adverse drug reactions (ADRs) cause 197,000 deaths annually in the EU, with a societal cost of €79 billion. The EU-funded UNLOOC project—Unlocking Data Content of Organ-on-Chip—aims to address this by developing organ-on-chip systems. These innovative devices simulate human organ responses, offering safer and more reliable testing alternatives.

“We are working in two areas: the replacement of animal testing and the development of personalized medicine,” says INESC-ID researcher Fábio Passos, who is actively involved in the project.

By advancing tools based on engineered cell systems (ECS), artificial intelligence, and high-throughput testing, UNLOOC seeks to transform preclinical testing, reduce ADRs, and lower drug development costs by up to €700 million per new drug.

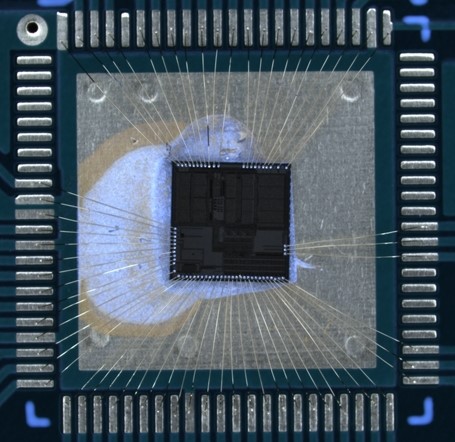

The project integrates ECS-based hardware and software, enabling precise environmental control (e.g., temperature, pH, oxygen) and parallelized testing across multiple channels. Jorge Fernandes, INESC-ID project coordinator notes that “microelectronics is a key enabling technology for these systems, to process, simultaneously in a small footprint, signals from large sensor arrays.” One key innovation is an application-specific integrated circuit (ASIC) developed by Silicongate. This ASIC interfaces with sensors to measure environmental parameters across up to 1,024 channels in a single digital system.

“To enable the development of cell structures similar to skin, liver, lungs, and other tissues, very specific conditions are required. These can only be achieved through the measurement and control of environmental variables like temperature, oxygen, pH, and conductivity,” explains Marcelino Santos, Silicongate co-founder and CTO.

Personalized medicine and disease research

INESC-ID is responsible for the sensor that monitors changes in the culture where lab-grown skin is placed. This skin, composed of chemicals and real cells, is immersed in a liquid containing electrical circuits. “The electronic component is what makes everything possible—without it, it would be impossible to monitor the activity of the artificial organ,” stresses Fábio Passos. The measurements are instantaneous, with the ability to perform thousands per millisecond. “One of its key advantages is its capacity for simultaneous readings, enabling hundreds of measurements at the same time,” Fábio adds. All this in a sensor that is a microchip measuring just 1mm x 1mm.

INESC MN is also part of the project and according to Diogo Caetano, the project coordinator at the institution, “the unique synergy between nanoelectronics circuits and sensors within the three PT partners will allow us to achieve precise and continuous monitoring in OOC systems.”

UNLOOC will validate its tools in five use cases across 10 European countries, benefiting academia, the pharmaceutical industry, and cosmetics production. The project aims to promote personalized medicine and advance disease research.

All this technology is possible because the “artificial” organs generate a set of biomedical signals with given voltages and currents that can be interpreted by the electronic circuitry. However, several challenges must be overcomed in order to meet the necessary resolution to interpret such signals. “In our case”, Marcelino explains, ”the resolution required to read the sensors necessitated the development of a new analog-to-digital converter (ADC). Previously, our sigma-delta ADCs were primarily used for temperature measurements, where a 12-bit resolution was sufficient. For the UNLOOC project, we are developing a 14-bit sigma-delta ADC with significantly higher energy efficiency than previous designs.”

The modular system, with a flexible number of analog channels monitored through a single serial digital interface (SPI), was specifically designed for this project. The SPI interface, typically used for reading and writing in a register bank, will use a prefix in the addresses to uniquely identify each ASIC. “There is great potential for healthcare applications, gaining traction with advancements in electronics,” notes Fábio Passos.

The applications developed and validated by UNLOOC will drive drug development, enable cosmetics production without animal testing, foster personalized medicine, and provide new insights into disease. Given the growing organ-on-chip (OOC) market, these solutions have significant economic potential. On average, they could reduce the cost of bringing a new drug to market by €170 million to €700 million. This approach positions Europe at the forefront of this burgeoning field, contributing to ethical, economic, and technological advancements in healthcare and drug development.

Text by Sara Sá, Science Writer | Communications and Outreach Office, INESC-ID / © 2025 INESC-ID

Images | © 2025 Silicongate